To place this all into viewpoint, obtaining the load of the consultant sample(s) may be the place to begin of any take a look at sieve Examination and dictates the accuracy of one's closing particle Evaluation benefits.

Sieves are subjected to hard use, irrespective of whether in the sieve shaker or with manual sieve strategies. Sample loads induce distortion from the woven-wire mesh and abrasion ends in a discount of wire diameters, enlarging the openings past appropriate limits. Other options for ongoing validation of sieve accuracy and conformity also are obtainable:

Commonly Requested Issues What's the usage of an ultrasonic separator? Ultrasonic separation permits much easier separation of bulk powders for instance metal powders, paints, chemical substances or food powders.

Nonetheless, For anyone who is dealing with particles that exceed 1” consistently, a 12” sieve may be right for you, as They are really a bit further and provide much more area for those larger particles to maneuver.

The wire cloth’s Qualities significantly effects sieve general performance. These incorporate the fabric, external things like temperature and humidity, and also the weave qualities, such as mesh rely and wire diameter.

Our gross sales, engineering, and challenge administration personnel start by developing a unified idea of your approach and targets in the completion of our Tailor made Quotation Request Type.

High quality Regulate: The use of sieves in pharmaceutical good quality Management ensures that the final goods meet up with the demanded requirements. By consistently examining the particle size distribution of raw resources and finished products, companies can keep regularity in their products. This consistency is important because it directly impacts the efficacy and safety with the medications.

This cookie is set by Addthis.com. This cookie is used for sharing of hyperlinks on social websites platforms.

Woven wire fabric is commonly used in sieve building, noticeably impacting the mesh size. The interwoven wires produce specific openings that ascertain the size of particles which can pass through.

Typical Reference Materials (SRMs) are precision-sized powders or glass beads to test the functionality of sieves and estimate helpful opening sizes. SRMs will also be used to ascertain the size of mesh openings if not acknowledged.

Given that we’ve covered the ins and outs of sieve mesh sizes, it’s time to apply this knowledge to choose the right sieve mesh size for the distinct demands.

Deciding on the appropriate sieve mesh size is really a significant determination that depends on the particle size distribution of the fabric, field-unique prerequisites, the intended software, check here and may benefit from pro help for best results.

It’s a sieve. It provides better filtration and catches solids and read more particles with its fantastic mesh, not like a colander, that has larger sized holes. Culinary preparations often use strainers, also called sieves.

How can ultrasonic know-how function for deblinding sieves and separators? Ultrasonic deblinding sieves and separators utilize high-frequency vibrations generated by a transducer mounted right on to the mesh screen. These vibrations produce a bouncing impact on the sieve surface, stopping particles from sticking or lodging to the monitor apertures.

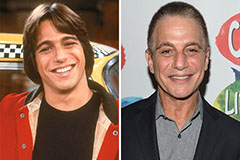

Tony Danza Then & Now!

Tony Danza Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!